- 705-946-9772

- domenic@nationalgroup.ca

- 297 Lemeul Rd, Gaffney, SC 29341, USA

Hard Face Cladding and Consumables

PRODUCTS

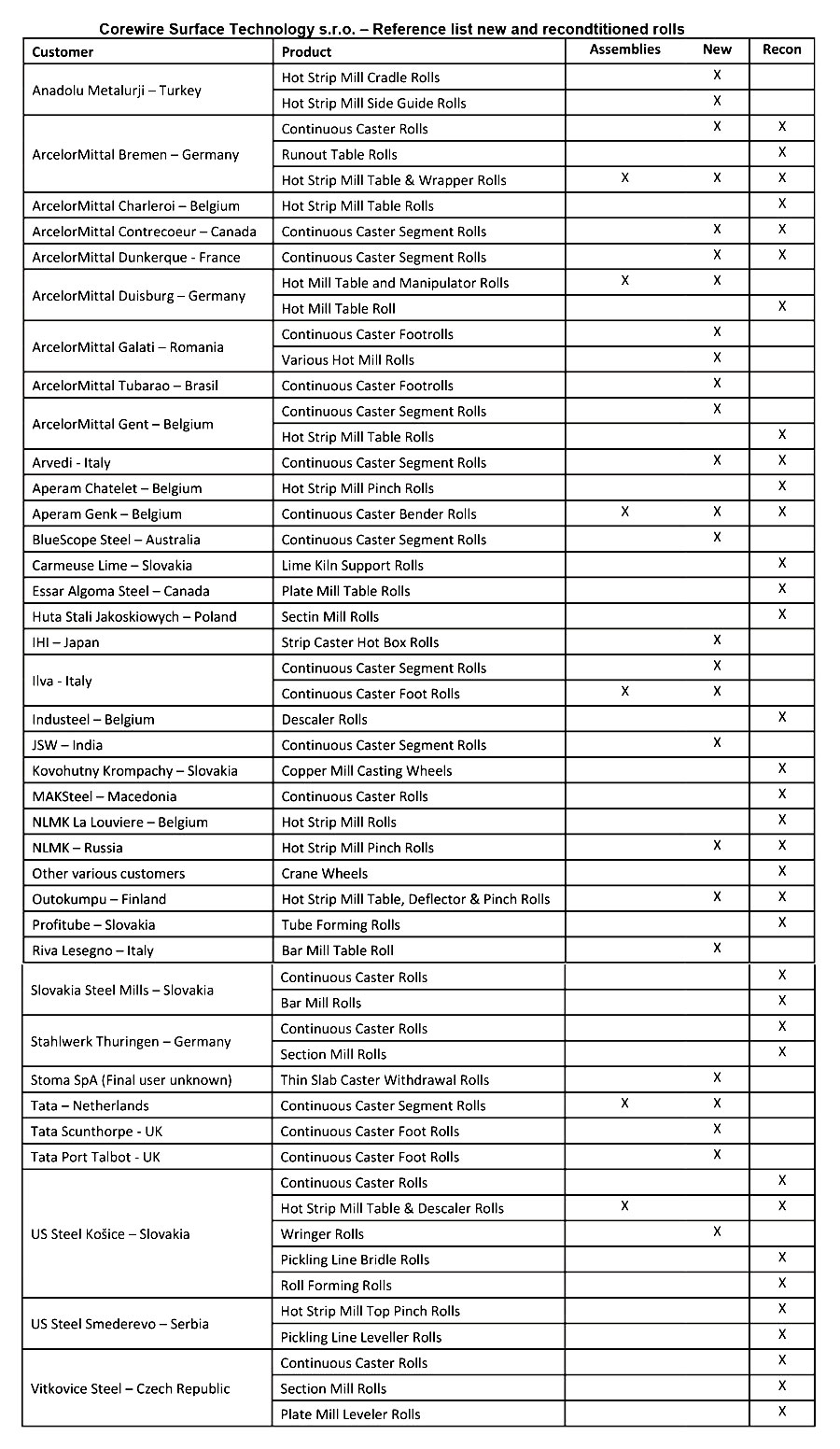

- Corewire Ltd has been in the business of manufacturing bespoke hard facing consumables for over 40 years.

- Specialized in steel mill roll cladding from continuous casters through hot mills, plate mills, pickling lines and further downstream.

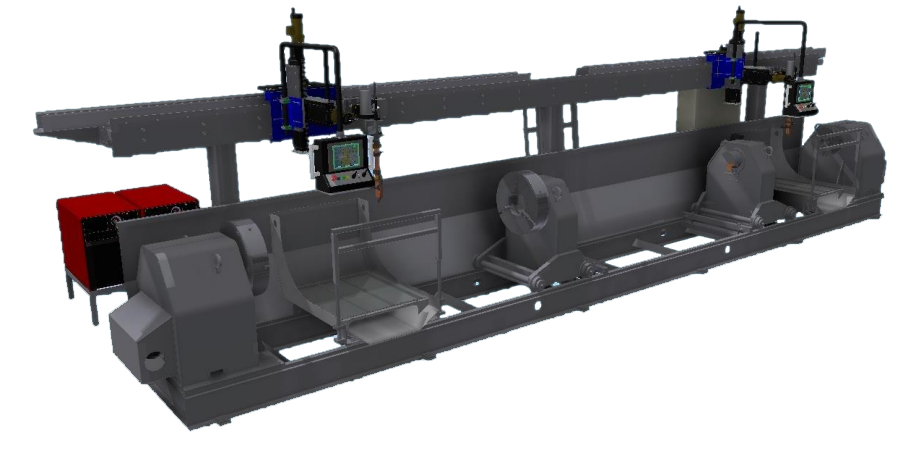

- Manufacturer of purpose-designed roll welding machines.

- Offering the consumables, purpose-built machines and technical support to global customers.

- Maintains global preferred supplier agreements with major steel conglomerates.

- Technical support and solution-based approach offered by staff coming from the steel industry vs. welding engineers simply offering a catalogue.

- Manufacture customer-specific consumables

- Customer specific procedures in order to optimize performance and reduce cost.

- Private labeling where applicable and needed •

- Think outside the box and explore new territories

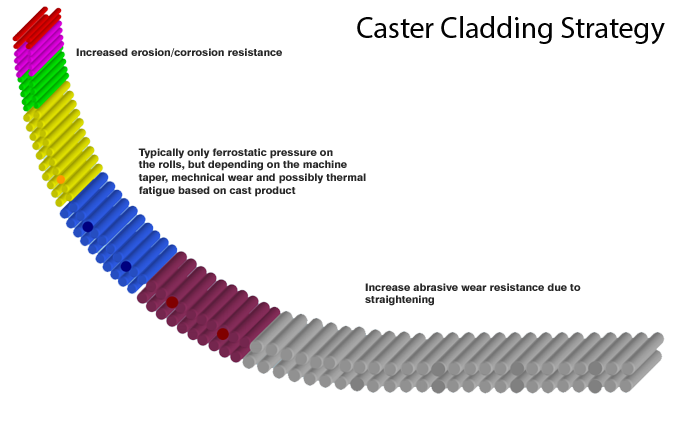

Each section of the caster has a different impact on the roll surface due to cooling, roll design, lubrication, cast product and function of the roll etc. Optimizing roll performance may result in different cladding materials for different sections.

Corewire always takes the approach of reducing long term and sustainable cost.

This may result in a slightly more expensive process to begin with, but result in an overall cost reduction due to increased life etc. The Total Cost of Ownership approach has now been firmly established with many customers. It is too simple to just go with the cheapest welding consumable…or the lowest bidder on rolls.

Corewire – other services

- HSM Looper Rolls

- HSM Runout Table Rolls

- Coil Box deflector rolls

- Pickling Line Entry Pulling Rolls and Leveler / Flattener Rolls

- Pickling Line Bridle Rolls

- Plate Mill Rolls (similar to HSM) reversing tables etc.Plate Mill Hot Leveler Rolls

Purpose built roll welding equipment. HMI controlled welding parameters optimizing surface quality

Corewire – Roll Welding Machines